About us

Zhangjiagang Friend Machinery Co., Ltd.

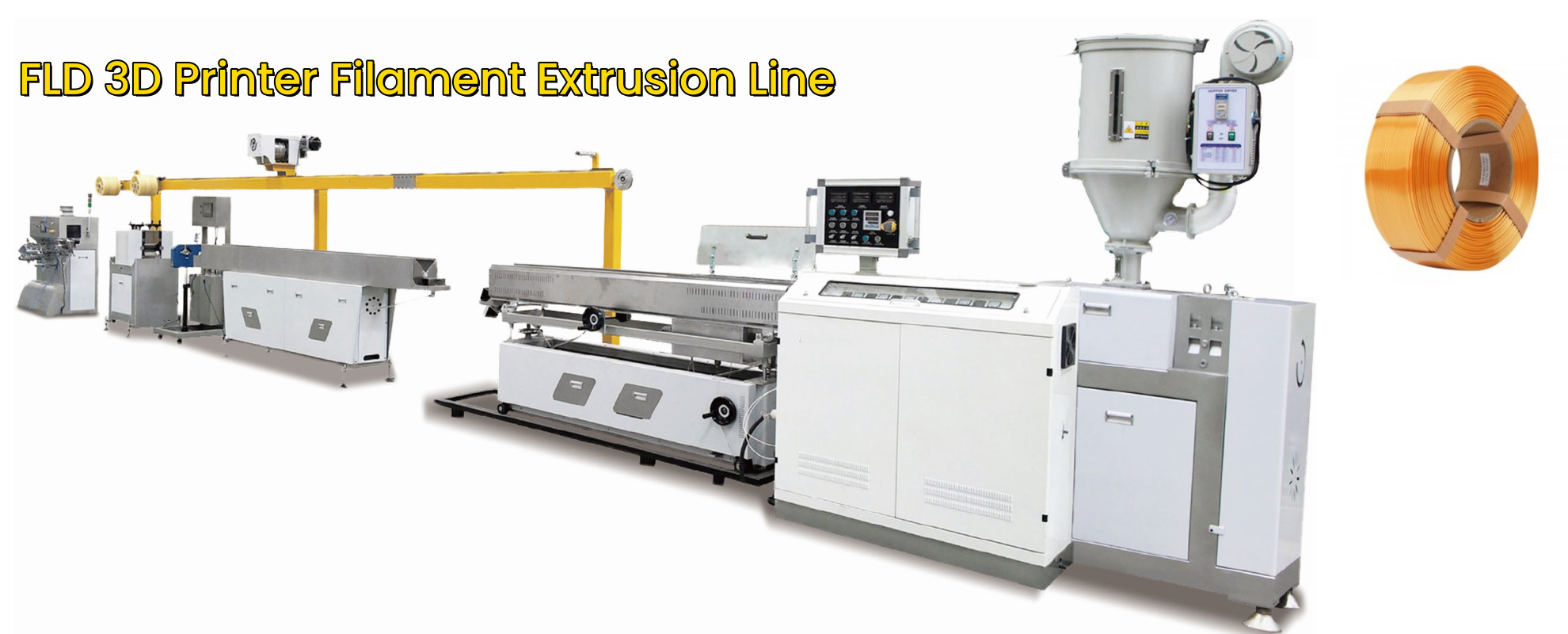

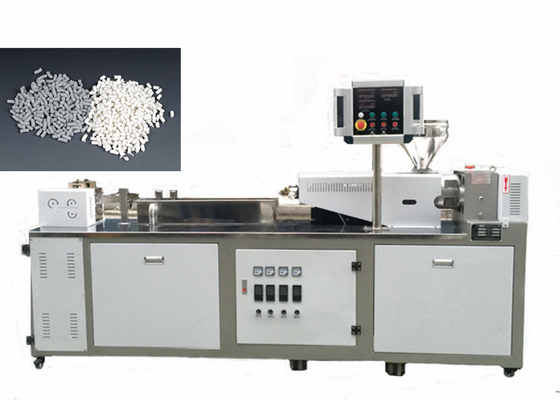

Zhangjiagang Friend Machinery Co.,Ltd was established in 2010 and is located in Zhangjiagang City, Jiangsu province, enjoying convenient transportation and beautiful environment. Our company covers an area of 9000 square meters and has 60 employees. We are specialized in producing plastic machine and have an annual production capacity of 500 million US dollars. Our company has rich experience in the plastic machinery making industry. Our main products include 3D filament production line, Plastic ...